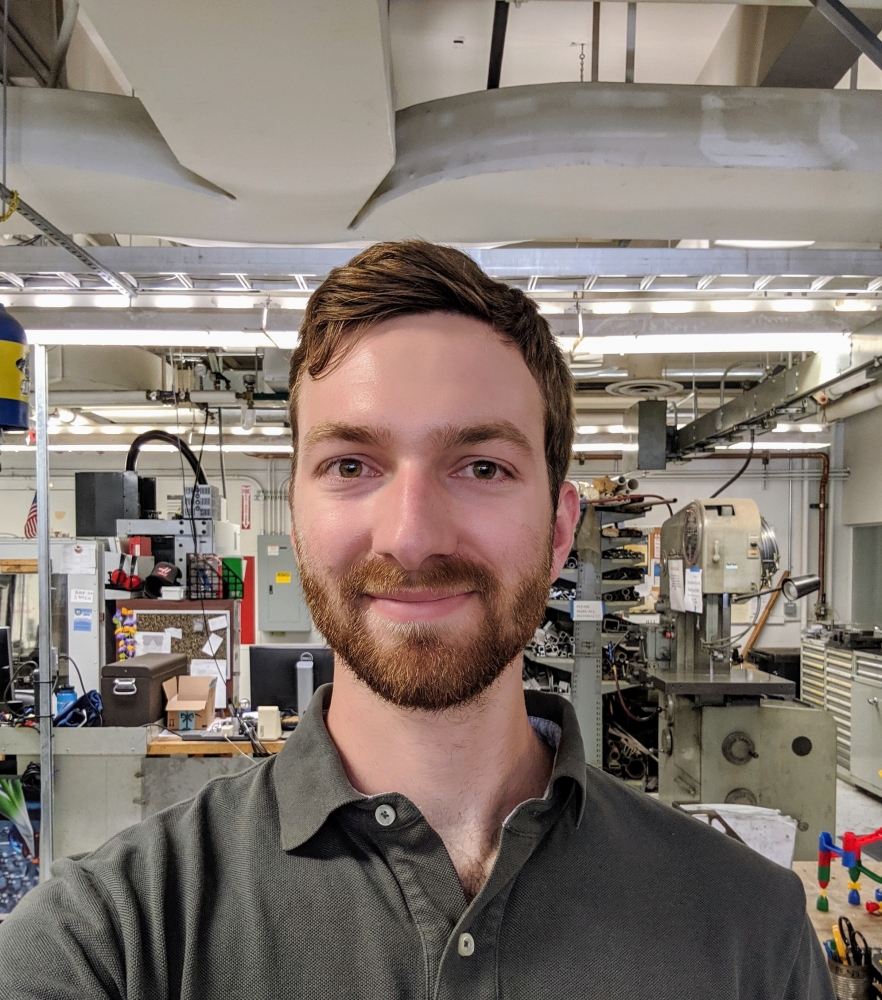

ME12S

Introduction to Machine Shop (1.0 Unit)

ME 12S is designed to introduce people to the machining process, such as reading blueprints, checking tolerances, and using conventional machines to make their parts; currently, the class is making a compressed air motor (below). This class is an excellent option and highly recommended to anyone who wishes to use the shop because it not only teaches you about basic machining principles, but also allows you to familiarize yourself with the machines and capabilities of the shop allowing for more ease and independence when working on individual university-related projects.Students use conventional mills, lathes, band saws, drill presses, etc. to machine the various parts of the compressed air motor from stock material. The class is offered every quarter except for summer; it is broken up into 7 sections of no more than 8 students each. Each section meets once a week for a 2 hour period. Brief lectures are held before each class to go over the various machining techniques that will be used to make the motor.

The class is open to anyone (other non-ME undergrads, grad students, etc.) who wants to take it, but ME majors have first priority. Non-ME majors wishing to add must crash at the start of the quarter. If you wish to crash ME 12S, please send an email to the Student Shop Supervisor Sean Linley or visit the shop during regular business hours before the start of classes.

Please visit the College of Engineering Machine Shop for more infromation about the facility.